Camber

Camber

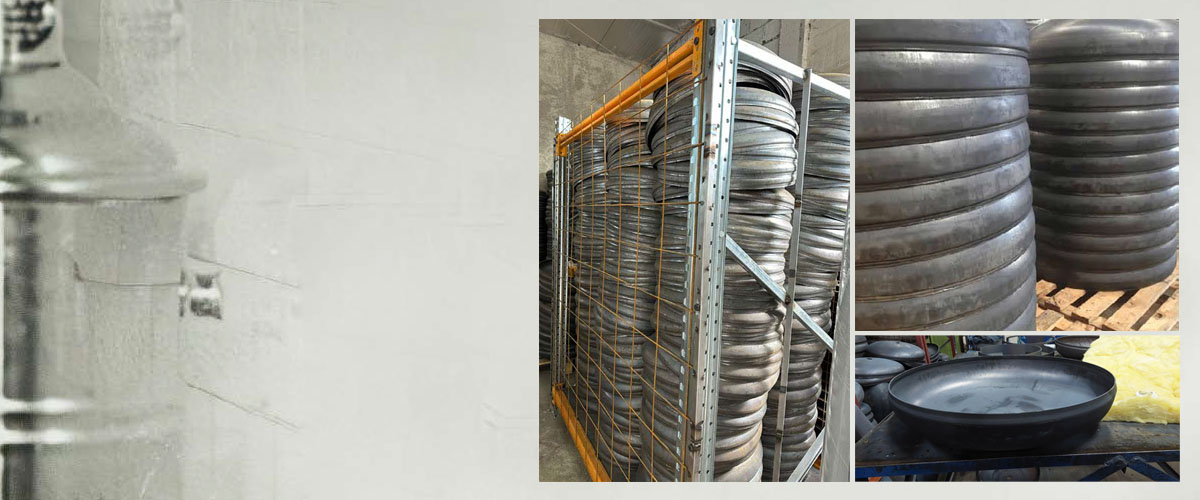

Dishing (Domed Ends) refers to the specialized process of shaping metal parts into a curved or domed form. This process involves providing a specific slope or curvature to a particular section of the material.

Get a Quote Now

Dishing (Domed Ends) refers to the specialized process of shaping metal parts into a curved or domed form. This process involves providing a specific slope or curvature to a particular section of the material.

It is widely used in industries such as storage tanks, piping, pressure vessels, and the automotive sector.

Types of Dished Ends

- Hemispherical Ends: Generally used in the production of large-scale high-pressure vessels.

- Torispherical (Torus) Ends: Commonly used for cylindrical parts and typically preferred in applications without extremely high pressure.

- Elliptical Ends: Primarily used when a specific geometric shape or aesthetic requirement is necessary.

Key Considerations in Dished End Production

Material Selection:

The type of material must be chosen based on the metal's strength, durability, corrosion resistance, and workability. Selection also depends on the specific application area where the dished end will be utilized.

Quality Control:

A rigorous quality control process must be implemented at all stages, from raw material quality to the final product. Precision measurement tools should be used to minimize deviations and errors.

Production Process:

Regular calibration and maintenance of production machinery are essential. Heat treatments may be applied to facilitate the shaping of the metal. Temperature control during heat treatment is vital for structural integrity.

Safety:

Safety:

Occupational safety regulations must be strictly followed throughout the production process. Machine operators must be fully trained in safety protocols.

Design and Engineering:

The design must adhere to engineering principles. CAD (Computer-Aided Design) software should be utilized to minimize margins of error, and both static and dynamic load calculations must be performed.

Assembly and Application:

Correct alignment and proper installation methods are critical during the assembly of dished parts. Functional and safety tests must be conducted post-assembly.

Cost and Time Management:

Efficiency should be optimized through continuous evaluation of new technologies and methods to manage both project costs and timelines effectively.

Conclusion

Dished end production is a process requiring expertise and precision. By combining correct material selection, meticulous manufacturing, quality control, safety measures, and sound engineering design, high-quality and reliable ends can be produced. A high-level production process ensures customer satisfaction by increasing both product quality and operational efficiency.